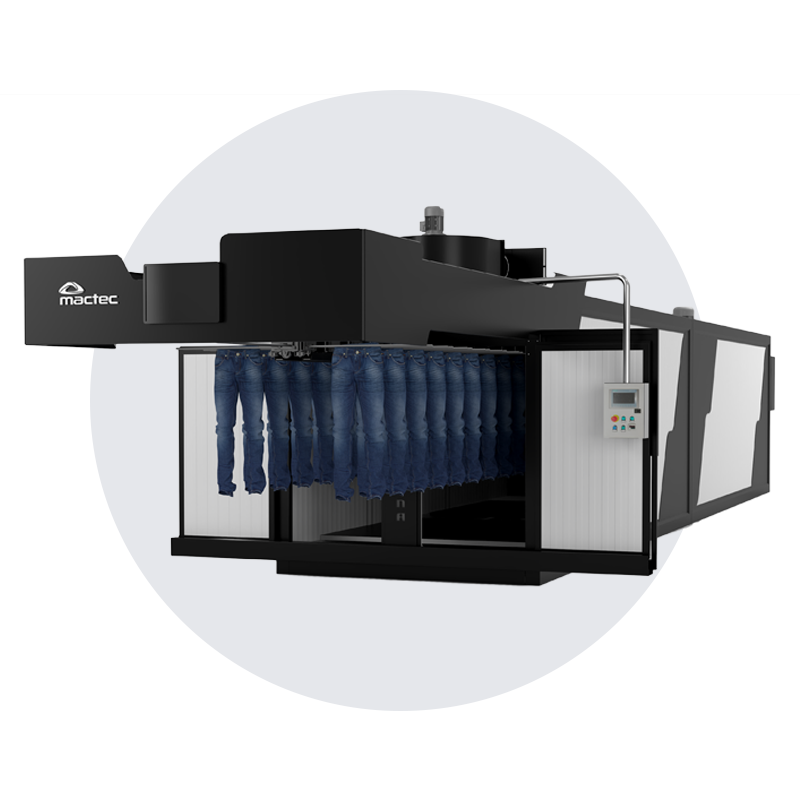

OVEN CATENA

CURING SECTION

Features

Technical specs

Dimensions

OVEN CATENA 11000 / 8500 / 5900

Length: 16800 / 14600 / 12840 mm

Width: 4130 mm

Height: 300 mm

Weight: 1050 / 790 / 528 kg

Productivity

1050 / 798 / 528 pcs/h

Power Supply

Gas / Diesel