THE RIGHT TECHNOLOGY FOR EACH STEP OF THE (DRY) PROCESS

TECHNOLOGIES

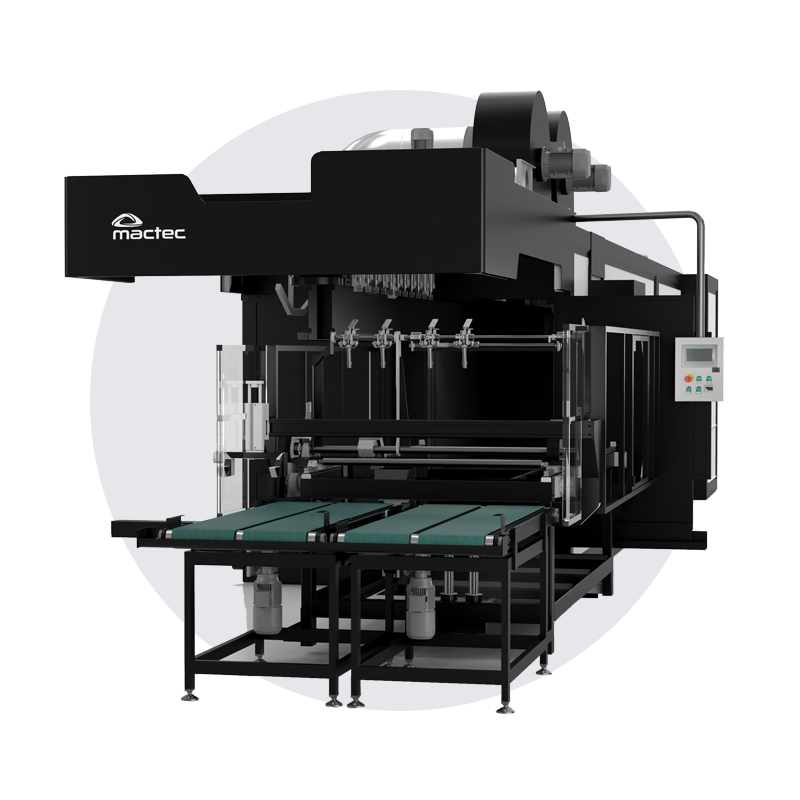

SECOMATIC

The automatic conveyor dryer for hanging garments

Secomatic revolutionizes the way we think about drying garments, thanks to its automatic loading and hanging system. Hanging garments drastically increases drying efficiency and product quality, and Secomatic allows you to reach the highest drying quality in the most sustainable way.

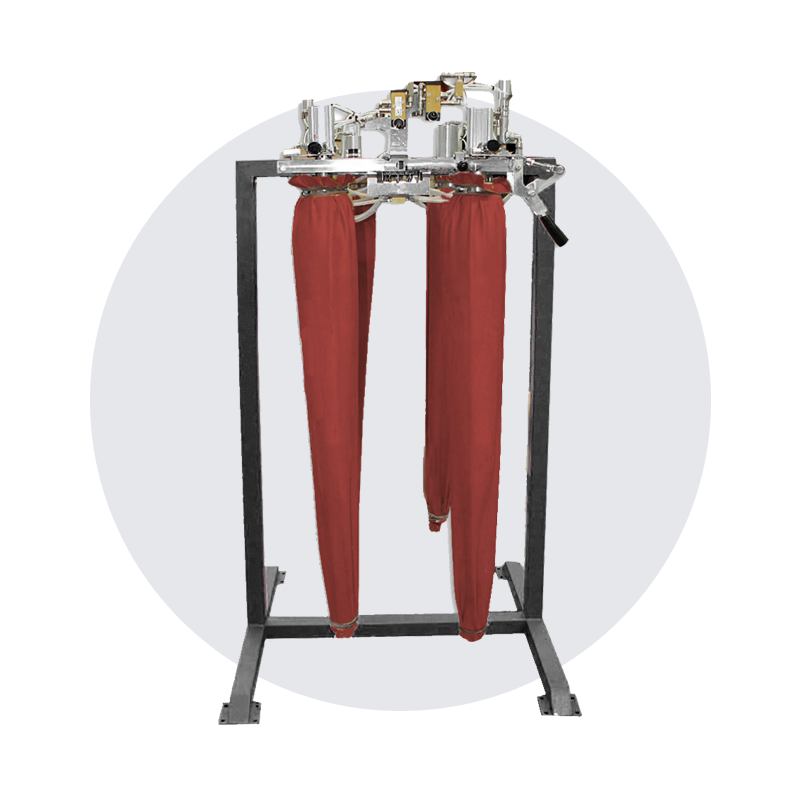

MPM

The Mold Preventing Machine

A Mold Preventing Machine designed to be implemented in the drying system of garments; right before the packaging phase. Most brands have strict requirements regarding the humidity left in the garments when packing them. MPM removes the excessive humidity to prevent mold from forming once the garments are packed.

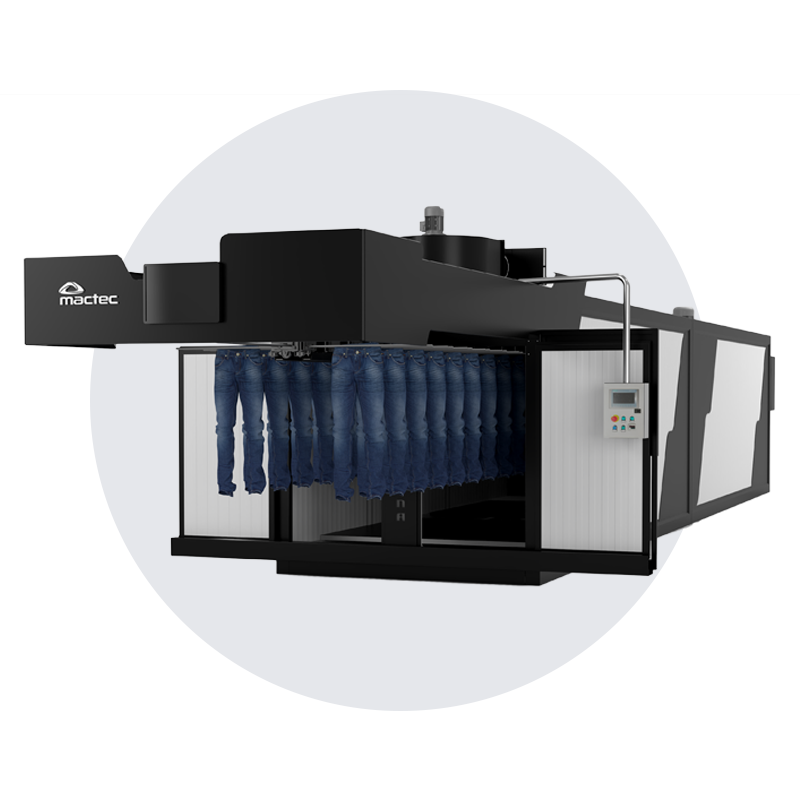

OVEN 2000

The curing oven for productions of around 10.000 pieces a day.

The Oven 2000 is designed to automatically start once its door is closed, enabling it to reach the desired temperature rapidly. Once the selected process is over, an automatized system pulls out the air, allowing you to extract the garments after only 3-4 minutes.

MARGHERITA

The best and fastest way to make 3D effects.

Using Margherita for the 3D effects allows you to obtain the highest quality product in a natural way, as well as a far more efficient and controlled process. Thanks to the doors, the airflow system, and the split process, Margherita grants you the highest productivity as well.

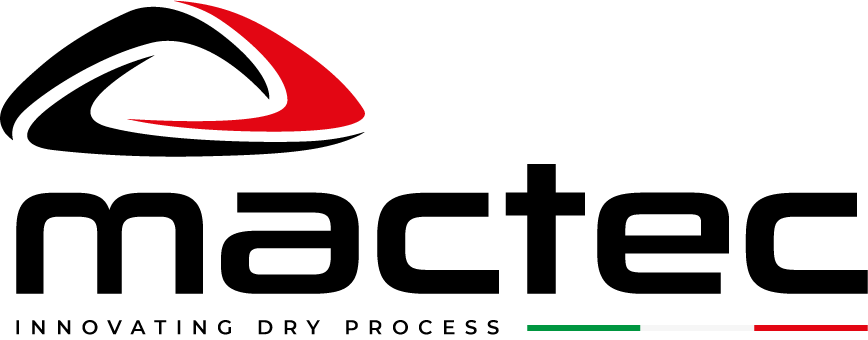

SPRAY CONVEYOR

The most efficient and sustainable Spraying system.

A conveyor spraying system equipped with a cabin entirely made of 316 stainless steel; and equipped with the most innovative technology to ensure maximum productivity and efficiency for your production line; while respecting the environment.